How to Pressure Cast

***Wear safety glasses while working with chemistry and using the pressure chamber.

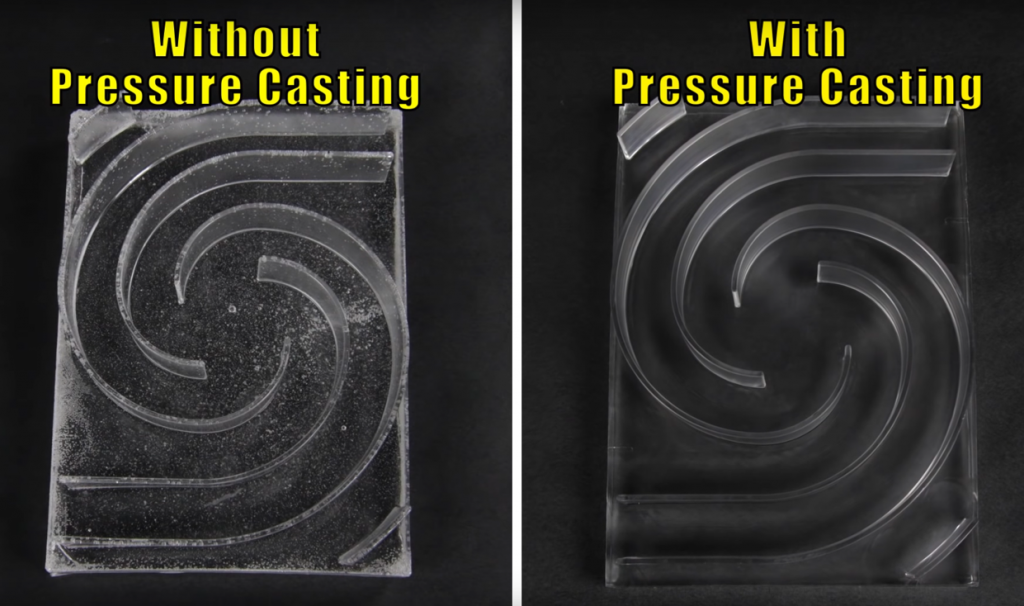

When working with resins and some mold rubbers, especially where clarity is important like for transparent materials, it is useful to pressure cast an object. Pressure casting is a process incorporating a pressure chamber and compressor to eliminate bubbles from a casting resin or mold rubber. This is also useful for a complex mold or object with thin parts where the liquid material might not normally flow into certain tight spaces. Using the pressure chamber is easy, even though it may look intimidating. Here is an example of a clear object with and without pressure casting.

Here are some basic instructions

- Mix your casting materials thoroughly

- Prepare your mold

- Pour casting material into mold

- Remove lid from pressure chamber and place mold into pressure caster

- Place the lid on the pressure caster and secure the lid by tightening the large wing nuts. Start with two diagonally across from each other and tighten them in tandem

- Connect the air line hose from the compressor to your pressure chamber

- Open the air pressure line and check the pressure gauge, it should read at 80 psi. Do not go over 80 psi! The pressure can be adjusted by turning the knob below the gauge clockwise to reduce the pressure and counter clockwise to increase the pressure.

- Once all wing nuts are tightened you can open the intake valve. You will see the pressure gauge on the pressure chamber increase, once it reaches 80psi close the intake valve.

- Remove the air hose, the pressure chamber will retain its pressure.

- Keep the material under pressure until it is cured. Consult your material technical details for the cure time of your material.

- At the end of cure time, unscrew the pressure valve from the chamber. Release air slowly from the chamber, wait until pressure reaches 0psi.

- Unscrew the wing nuts and remove the lid from the pressure chamber

- Remove the mold from the pressure chamber

- Demold your model from the pressure chamber