- Clear Pocket

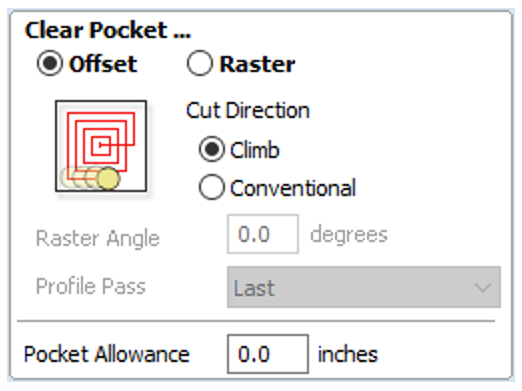

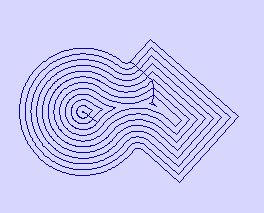

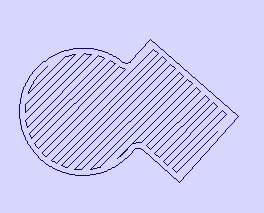

There are two choices of the type of fill pattern that will be used to clear away the area to be machined with the Pocket Toolpath, Offset and Raster.

Offset Calculates an offset area clearance fill pattern to machine inside the selected vector(s). Options for Cut Direction to be either: Climb (CCW) cutting direction Conventional (CW) cutting direction.

Raster Calculates a Raster based area clearance fill pattern to machine inside the selected vector(s). Cut Direction for the final pass to be either:

– Climb (CCW) cutting direction

– Conventional (CW) cutting direction

- Raster Angle

- Between 0 and 90°, where 0° is parallel to the X axis and 90° parallel to the Y axis.

- Profile Pass

- Used to clean up the inside edge after machining the pocket. This can be done either before the rastering (First) or after the rastering (Last). If ‘No Profile Pass’ is selected, you will need to calculate a profile pass manually to machine the pocket to size.

- Pocket Allowance

- This option is used to leave material on the inside of the pocket for the Profile Pass to clean-up. This is often very useful for ensuring the cutter does not mark the edge surface of the pocket when roughing out.

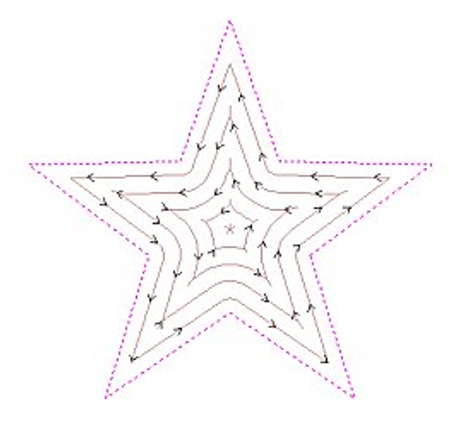

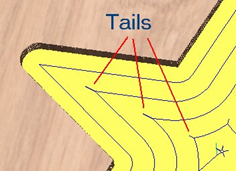

Note: When the stepover for a pocket fill is greater than 50% of the cutter/tip diameter the software automatically adds ‘Tail’ moves to the corner regions on the toolpaths to ensure material is not left on the job. You can see these in the diagram of a star being pocket machined below: